If you’ve ever worked on a project involving tubing or air systems, you’ve likely come across push-to-connect fittings. They’re incredibly useful, especially for DIY enthusiasts and professionals alike. But if you’re new to using 8mm push-to-connect fittings, you might be wondering how to install them properly.

Don’t worry! In this guide, we’ll walk you through 5 simple steps to make sure you get a perfect connection every time. Let’s dive right in!

What Are 8mm Push-to-Connect Fittings?

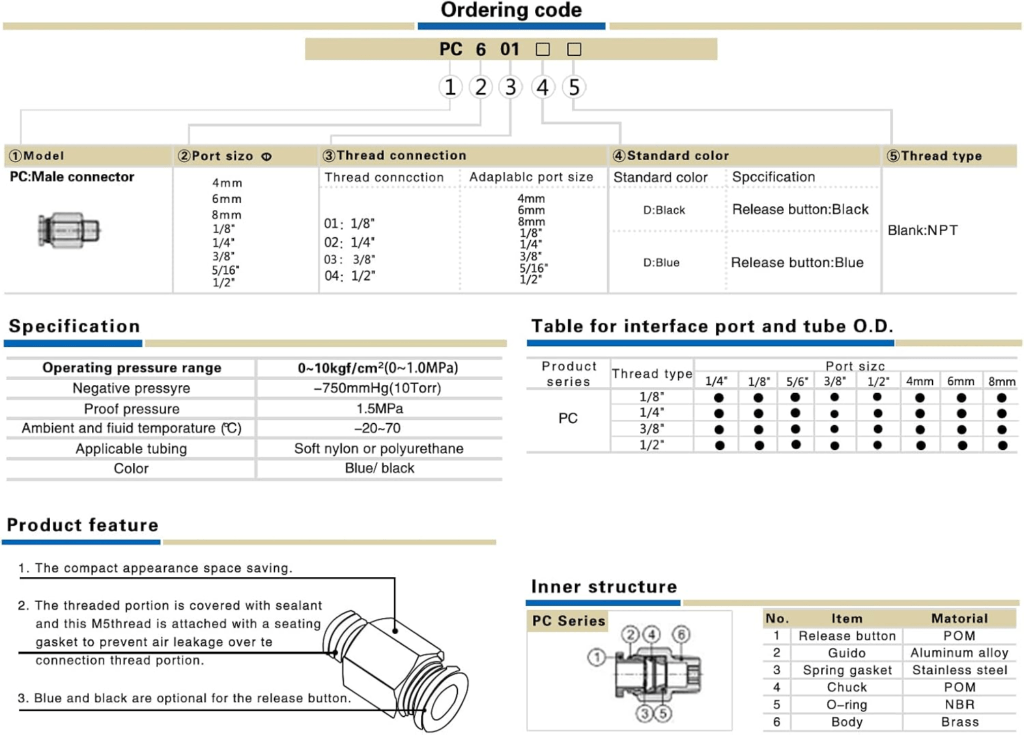

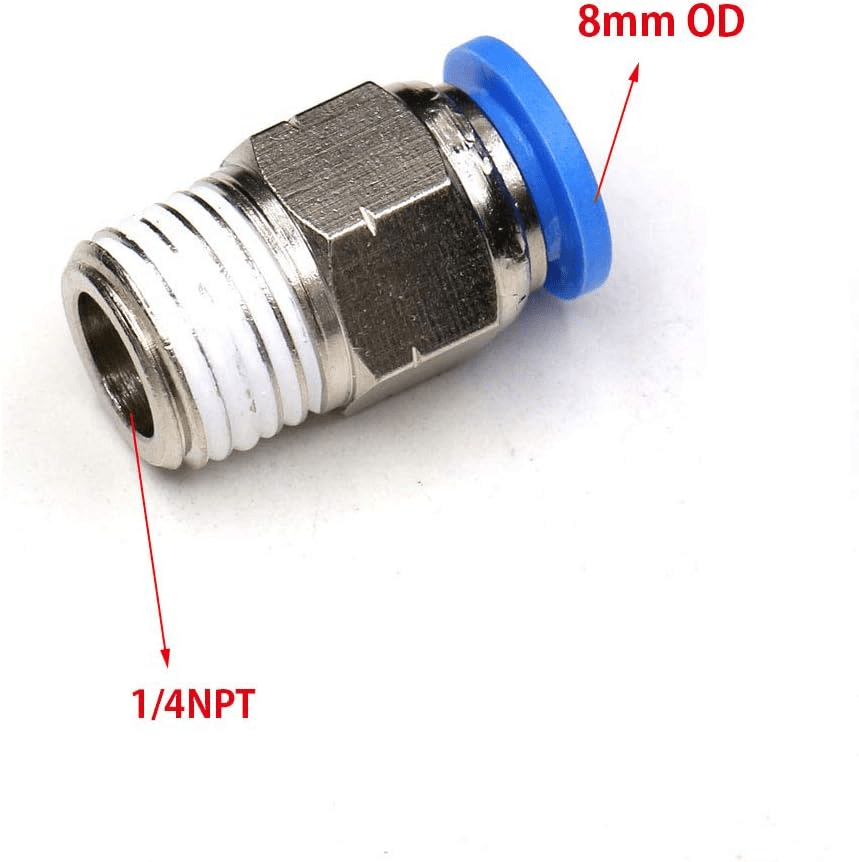

Before jumping into the steps, it’s good to know what these fittings are. 8mm push-to-connect fittings are small but powerful tools designed to quickly connect tubing without the need for special tools, clamps, or adhesives. They’re widely used in pneumatic systems, water lines, and more because of their reliability and ease of use.

So, if you’re looking to install one, here’s the easiest way to do it!

Step 1: Gather Your Materials

Before you begin, you’ll need a few things to ensure a smooth installation:

- 8mm tubing (the right size matters!)

- 8mm push-to-connect fittings

- Tube cutter or sharp knife

- A clean cloth to wipe off any debris

Pro Tip: Always ensure the tubing matches the diameter of the fittings. In this case, you’ll need 8mm tubing for the 8mm fitting. Incorrect sizing can lead to leaks or improper connections.

Step 2: Cut the Tubing Cleanly

The key to a perfect connection starts with a clean cut. Use a tube cutter or a sharp knife to cut the tubing straight across. A clean, straight cut ensures a proper seal inside the fitting.

Avoid Jagged Edges! Jagged edges can cause the fitting to malfunction and may result in leaks down the road.

Step 3: Inspect and Clean the Tubing

Now that you’ve cut the tubing, give it a quick inspection. Make sure there are no cracks, debris, or uneven surfaces on the end. Wipe off any dirt or dust with a clean cloth.

Why is this important? Any debris or imperfections can prevent a secure connection, leading to potential system failures or leaks.

Step 4: Insert the Tubing into the Fitting

Here comes the magic moment! Simply push the tubing into the fitting until you feel it “click” into place. You’ll feel resistance as it locks in securely. Make sure it’s pushed in all the way to prevent leaks.

How do you know it’s secure? Give the tubing a gentle tug to make sure it’s locked in tight. If it doesn’t budge, you’ve got it right!

Step 5: Check for Leaks

Before wrapping up, always check for leaks. If you’re working with an air or water system, turn it on and observe the fitting. If you see any bubbles (for air) or drips (for water), the connection might not be secure.

No leaks? Great! You’ve successfully installed your 8mm push-to-connect fitting.

Why Use Push-to-Connect Fittings?

You might be wondering, why not just stick with traditional fittings? Here’s why push-to-connect fittings are a game-changer:

- Tool-Free Installation: No need for wrenches or adhesives.

- Quick and Easy: Saves time, especially for large projects.

- Durable: Offers a secure, long-lasting seal.

- Reusable: Easy to disconnect and reconnect if needed.

Troubleshooting Common Issues

If things don’t go smoothly, don’t worry. Here are a few tips to troubleshoot common problems:

- Tubing Not Locking In? Double-check that you’re using the correct size of tubing for the fitting. Make sure it’s inserted all the way.

- Leaks at the Connection? This could mean the tubing wasn’t cut cleanly or inserted fully. Remove the tube, recut it, and try again.

- Difficult to Remove? Press the release ring on the fitting while pulling the tubing to release it.

FAQs About 8mm Push-to-Connect Fittings

Before wrapping up, let’s tackle some frequently asked questions that might be on your mind. Understanding these will help you use your fittings more effectively and avoid common mistakes.

1. Can Push-to-Connect Fittings Handle High Pressure?

Absolutely! Push-to-connect fittings are designed to handle high-pressure systems, depending on the material they’re made from. Most fittings can comfortably handle pressures up to 150 PSI or more, which makes them perfect for both air and water systems. However, always check the manufacturer’s specifications to be sure you’re within safe limits for your specific application.

2. Are These Fittings Suitable for Hot and Cold Temperatures?

Yes! These fittings can generally handle a wide range of temperatures. For air and water applications, they typically work well in temperatures ranging from 0°C to 60°C (32°F to 140°F). Again, check your product’s specifics to make sure you’re within safe temperature limits.

3. Can I Reuse Push-to-Connect Fittings?

One of the best things about push-to-connect fittings is that they’re reusable! If you need to make adjustments or reroute your tubing, simply press the release ring and pull out the tubing. You can then reuse both the fitting and the tubing as long as the tubing remains in good condition.

4. How Do I Disconnect a Push-to-Connect Fitting?

It’s super simple. To disconnect, all you have to do is:

- Press down on the release ring located at the base of the fitting.

- While pressing the release ring, pull the tubing out gently.

Once you’ve done that, the tubing will pop right out, and you can reuse the fitting.

5. Do Push-to-Connect Fittings Work for Gas Lines?

While some push-to-connect fittings are rated for gas lines, many are designed for air and water applications. If you’re working with gas, always make sure you’re using fittings that are specifically rated for gas use, as safety is critical in these systems.

Best Practices for Long-Lasting Connections

Now that you know the basics of installing 8mm push-to-connect fittings, let’s talk about a few best practices to ensure that your system remains strong and leak-free for the long haul:

- Inspect Regularly: Even though push-to-connect fittings are incredibly reliable, it’s always a good idea to inspect them regularly, especially if you’re using them in a critical system like air compressors or water lines.

- Avoid Excessive Bending: While tubing is flexible, too much bending near the connection point can lead to premature wear or leaks. Try to use elbow fittings or clips to guide the tubing smoothly.

- Use Proper Tubing Material: Different fittings are compatible with different types of tubing, such as polyurethane, nylon, or polyethylene. Always make sure your tubing material matches the fitting requirements for optimal performance.

Why 8mm Push-to-Connect Fittings Are a Must-Have

Whether you’re a professional in the field or just a DIY enthusiast, push-to-connect fittings are a game-changer. Here’s why they’ve become so popular:

- Speed: These fittings cut down installation time drastically. No more struggling with wrenches or adhesives—just push, and you’re done!

- Versatility: You can use them in various systems—pneumatic, hydraulic, water supply lines, and more.

- Durability: Built to last, push-to-connect fittings offer long-term reliability, making them a go-to choice for industrial and residential projects.

- Cost-Effective: While they may seem slightly more expensive upfront, the time and effort saved during installation make them a cost-efficient choice in the long run.

- Easy Adjustments: Need to change your setup? Simply press the release ring, and you can remove the tubing and refit it in seconds.

Bonus Tips: Making the Most of Push-to-Connect Fittings

If you’re ready to level up your installation game, here are a few more bonus tips to help you get the absolute best out of your 8mm push-to-connect fittings:

1. Always Keep Spare Fittings on Hand

When working on any project, it’s always a good idea to have a few extra fittings. Accidents happen—maybe you lose one, or perhaps a connection just doesn’t seem right. Keeping spares will save you the hassle of running back to the store mid-project.

2. Store Your Tubing Properly

Did you know that improperly stored tubing can cause problems during installation? If tubing gets kinked or bent, it might be difficult to get a secure connection with your push-to-connect fittings. Always store your tubing in a cool, dry place where it can remain straight and untangled.

3. Use Tubing Clips for Clean Installations

Want to keep your setup looking clean and professional? Use tubing clips to secure your lines in place. Not only do they make your project look more polished, but they also help prevent wear and tear by reducing unnecessary movement in the tubing.

4. Check Compatibility

Make sure that the fittings and tubing you’re using are compatible with each other. Different systems (air, water, gas) require specific materials and designs to function safely and efficiently. Double-check that you’re using the right 8mm fitting for your specific project.

5. Keep the Fittings Clean

Dirt, dust, and grime can build up inside the fittings over time, potentially leading to leaks or reduced performance. Always ensure that both the tubing and fittings are clean before connecting them. A quick wipe with a cloth can make all the difference.

Common Mistakes to Avoid

Even though installing push-to-connect fittings is easy, there are some common mistakes that can cause issues down the line. Here’s what to watch out for:

1. Not Pushing the Tubing in Far Enough

This is probably the most common mistake. If the tubing isn’t fully inserted into the fitting, it won’t lock in place, and you’ll have leaks. Always double-check by pulling the tubing lightly to ensure it’s properly connected.

2. Using the Wrong Type of Tubing

Not all tubing is created equal. Make sure you’re using tubing that is compatible with your specific push-to-connect fittings. Using the wrong type or size can result in poor connections or even damage to the fitting.

3. Overly Tight Bends in the Tubing

While push-to-connect fittings are flexible and convenient, the tubing can still be sensitive to excessive bending. Over-bending can weaken the connection or cause stress at the connection point. Use elbow fittings or gently curve the tubing to prevent this issue.

4. Skipping the Leak Test

You’ve followed all the steps, but you’re in a rush and forget to test for leaks. Big mistake! Always test your system after installation. Turn on the system, whether it’s water or air, and check each fitting for leaks. A few seconds of inspection can save you hours of frustration later.

Push-to-Connect Fittings: Are They Right for Your Next Project?

If you’re still on the fence about whether push-to-connect fittings are right for you, let’s review why they’re so widely loved in the world of DIY and professional projects:

- Time-Saving: Whether you’re an experienced professional or a beginner, the time saved with push-to-connect fittings is unbeatable.

- Tool-Free Installation: No need for wrenches or sealants—just push, connect, and you’re done.

- No Experience Required: These fittings are incredibly beginner-friendly, making them ideal for first-timers.

- Long-Term Durability: Once installed correctly, these fittings offer a secure and reliable connection that will last for years.

Final Thoughts

Push-to-connect fittings, especially the 8mm variety, are a fantastic option for both professional and home projects. They’re reliable, fast, and easy to use, making them an essential tool for plumbing, pneumatic systems, and more. By following the 5 easy steps outlined in this guide, you’ll have leak-free, secure connections in no time.

So, what are you waiting for? Start your next project with confidence, knowing that push-to-connect fittings will make your life a whole lot easier!

Share Your Experience!

Have you tried using 8mm push-to-connect fittings before? How did it go? Drop your experiences, tips, or any questions in the comments below. We’d love to hear from you and help each other out!

If you found this guide helpful, don’t forget to share it with your fellow DIY enthusiasts or professional colleagues. Let’s make plumbing and pneumatic projects easier for everyone!